Rigid vs Flexible Sprinkler Hose…..

Should we be using flexible sprinkler hose?

Flexible sprinkler hoses vs. rigid pipe

The adoption rate of flexible sprinkler hoses over traditional rigid pipe has steadily increased throughout the years. While the reasons for the rapid increase in popularity have focused on the labour savings and markedly improved project completion rates, there are several critical performances and safety benefits flexible sprinkler hoses provide over the traditional rigid pipe.

Foundations settle and ceilings can shift and sag over time, in some cases due to seismic activity. This presents a problem to the threaded hard pipe arm-over, specifically with respect to the sprinkler position in relation to the ceiling surface. By code, hard piping is required to be anchored to the building structure separate from the ceiling structure. Because of this decoupling between the pipe and ceiling, the sprinkler elevation relative to the finished ceiling surface cannot always be guaranteed to remain constant.

Under an extreme sagging condition of the ceiling surface, a sprinkler can become excessively recessed above the ceiling surface over time, potentially to an installed condition considered to be outside its agency listing or approval.

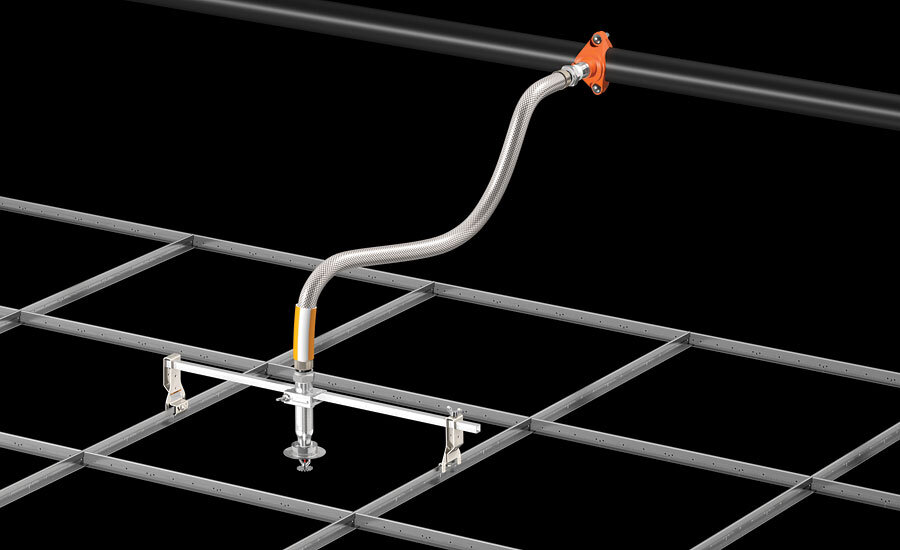

What this means is in the event of a fire, the sprinkler’s operational response time and spray pattern characteristics would be severely impacted, thereby allowing the fire to grow unchecked in the affected area. In contrast, a flexible sprinkler hose is required (by code, its listings and installation instructions) to be securely attached with an anchoring bracket to the ceiling’s structural elements, such as suspended T-grid ceiling channels or wood/metal joists or studs.

This positive bracket attachment to the ceiling structure ensures the elevation of the sprinkler in relation to the ceiling surface remains consistent over time. The inherent adjustability of the flexible hose accommodates the expansion, contraction and settlement of the ceiling structure, preserving the designed operational response and water distribution characteristics of the sprinkler.

Braided vs. non-braided hose design

While listed and approved to meet the same test requirements, flexible sprinkler hoses have vastly different design constructions. Most are manufactured from an austenitic grade of stainless steel; however, some designs are braided hoses, while others are non-braided (corrugated).

Additionally, subsets of each may have a wide pitch or narrow pitch convolutions – again, each having some very important trade-offs affecting key performance characteristics of a hose, including minimum bend radius, flexibility and pressure resistance.

Braided sprinkler hoses are designed with an external stainless-steel wire woven sleeve providing the necessary strength to withstand internal forces from system pressures, while the corrugated tubing underneath is able to remain relatively unaffected and flexible. In contrast, non-braided hoses rely on the tube wall alone to provide both strength and flexibility. The non-braided hose’s convolutions are farther apart (wide pitch), thereby reducing flexibility and increasing stiffness.

Because this type simultaneously must maintain pressure resistance while attempting to provide flexibility, albeit significantly diminished, the non-braided type falls short of fully reconciling these two critical features. Comparatively, braided hoses can withstand higher pressures than non-braided hoses without permanent elongation or deformation. Braided hoses typically also are capable of achieving a smaller bend radius, permitting a greater number of bends and resulting in the ability to accommodate installations in tighter, lower-clearance locations.

The external braiding also provides vibration attenuation properties in a high-flow condition and an added level of external abrasion protection. However, the convolution (or wave) profile, geometry and number of convolutions per unit length, regardless of whether an external braid sleeve is present or not, have the greatest influence on flexibility.

Wide pitch hose, either braided or non-braided, is more difficult to bend due to its inherently stiff cross-section and is more susceptible to kinking upon installation. Kinking, defined as a reduction in the cross-sectional area because of inducing a bend beyond its limits, can occur during installation, which results in a deleterious effect on hydraulic friction loss and corrosion resistance.

In other words, if a hose is kinked, water delivery to the sprinkler head could be diminished and the stresses induced in the kinked tube wall also can contribute to a decrease in corrosion resistance over time. In contrast, a narrow pitch hose provides greater flexibility because of the increased number of convolutions per unit length, resulting in less effort to bend, and in many cases eliminates the possibility of kinking.

Regulatory testing and approvals

Over the past 10 years, industry-leading independent approval agencies worldwide have developed standards governing the performance and manufacturing requirements of flexible sprinkler hoses and their anchoring brackets. While each of these standards is somewhat different in test methodologies, flexible sprinkler hoses with UL, FM, VdS, LPCB and CCCf listings and approval, have met some of the most rigorous testing protocols required of a fire sprinkler system product.

During initial type-testing of a design being evaluated for agency approval, each model of flexible sprinkler hose and its anchoring bracket is subjected to a series of controlled vibrations at varying frequencies and displacements. Connected to a branch pipe and anchored to simulated ceiling grid structures, the flexible sprinkler hose assembly is subjected to 90 hours of vibration cycles in each three-dimensional axis from 18 to 37 hz and at a maximum displacement of about 1/8 in.

Following the vibrational fatigue condition, the hose assembly must pass hydrostatic pressure tests to multiple times the rated working pressure without leakage. Additionally, approved flexible sprinkler hoses are subjected to cyclical fatigue tests, U-bending a hose at its minimum allowable bend radius upwards of 50,000 times. Again, it must pass hydrostatic pressure tests without leakage at several times its rated working pressure.

To meet additional requirements established by regulatory agencies, all manufacturers are required to conduct factory pressure tests on 100% of their flexible sprinkler hose production. These tests are intended to ensure leak-tight performance at a pressure of up to twice its rating. Also, random samples are required to be taken at periodic intervals to perform additional required quality checks, such as hydrostatic burst testing, elongation under hydrostatic pressure and dimensional checks. At the manufacturer’s discretion, this also may include random testing of chemistry and micro-hardness of the tube and braiding to ensure material quality, process consistency and that the product remains in the specification.

Similar to any listed or approved fire protection product, the regulatory agencies conduct periodic audits at each manufacturer’s production facility. Agency auditors will check records of the mandatory production testing, compare product drawings with actual production parts, verify the listing or approval mark is applied correctly and conduct an overall survey of the manufacturing process. This activity is designed to ensure flexible sprinkler hoses and anchoring brackets consistently are produced to the manufacturer’s specifications and continuously meet the performance levels defined by the agency’s standards.

Today, there are a wide range of flexible sprinkler hose models, coupled with an equally large selection of brackets, fittings and other accessories available for a broad range of building and construction types, system designs and water delivery requirements. Flexible sprinkler hoses not only install faster than hard pipe, but more importantly are able to accommodate ceiling shifts and sagging over time, ensuring sprinklers remain at their original installed elevation.

Narrow-pitch braided hoses permit a smaller bend radius allowing for installation in tight spaces and significantly reduce or eliminate the potential for kinking. When manufactured under robust quality systems, subject to periodic audits, and carrying global product approvals, flexible sprinkler hoses are able to help ensure sprinkler systems remain reliably in service and ready to provide their rated fire suppression capability in any critical event.

As building owners, insurance underwriters, regulatory agencies and authorities-having-jurisdiction all require an increasingly high level of performance, safety and reliability of a fire sprinkler system throughout its life, these products have become an easy choice in meeting all these requirements.

Design criteria for Fire Sprinklers for Minor Works

The adoption rate of flexible sprinkler hoses over a traditional rigid pipe in new installation, as well as minor work area within Australia, has grown dramatically over the years. Unfortunately, installers have been using these Flexible sprinkler hoses without taking into account the frictional loss shown on the datasheets, these are displayed in also equivalent pipe length.

Under AS2118.9- 1999 Minor Works and AS2118.1-2017 in the section Minor Works the sprinkler dropper from the main range pipes usually are 20 to 25mm, under the Standards mention the maximum pipe length is 14 meters of the rigid tube which is a decent length. However, these flexible sprinkler hoses have an equivalent pipe length which reduces this length dramatically.

For example, the data sheets that I have come across have

1200mm flexible sprinkler hose equivalent to 22 metre or rigid pipe;

1500mm flexible sprinkler hose equivariant to 27 metre or rigid pipe; and

1800mm flexible sprinkler hose equivariant to over 30 metre or rigid pipe.

These flexible sprinkler hoses were only ever designed for an office building with shallow ceiling voids and coming off 32mm ranges. They would not comply in most cases on minor works jobs, as most droppers are 20 to 25mm. There is only a small quantity of flexible hoses that can be used of a 20 or 25mm rigid pipe. However, I have found a 1200mm flexible hose that has an equivalent length of 9.85 metre, which leaves around 4 metres to comply with the 14 metres required within AS2118. Best used in the situations like shopping centres and where ceiling voids have a void height of more than 4 or 5 metres.

It would be interesting to see how many ‘Hyena Fire Sprinkler Calculations’ have the correct flexible hose used in the calculation, expecially as each manufacturer has a different equivalent pipe lengths for their brand of flexible sprinkler hoses.

Every building has been custom designed with regards to the density of water flow at each sprinkler. This is the reason behind the 14 metres and also to achieve a minimum of 60 litres a minute.

You could question, why then does the rigid pipe not have a bracketing system to the ceiling grid like the flexible sprinkler hose? If the rigid pipe was to bracketed then you would not have the sprinklers in the ceiling space as they would stop the ceiling from sagging and provide the ceiling more support.

Please take some time to comment.

I would love to hear your thoughts on these flexible sprinkler hoses, partcularly as sprinkler fitters generally love installing them! However we need to educate more, as many sprinkler fitters, many I have personally asked, did not know of these Standards and simply install these flexible sprinkler hoses because their supervisor brought them to site; or they were shown on the drawings; or they just thought it was all ok because we have they have always used them. There has to be more understanding of the Cause & Effect of important installation decisions, because we all need more education when it comes to Life Safety Equipment.